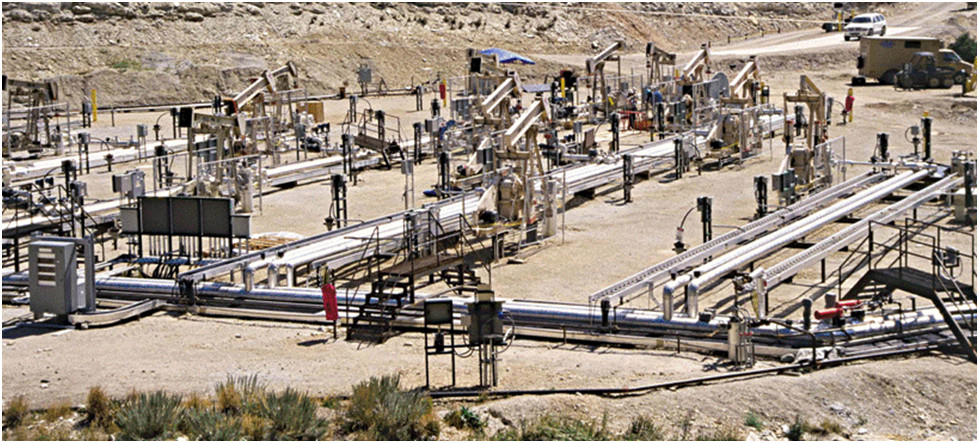

Unconventional oil and gas refers to hydrocarbons that are obtained through techniques other than traditional vertical well extraction. Our Client is a major oil and gas company that is seeking to monetize unconventional oil and gas resources in US region with over 1 trillion barrels of oil reserves. Presence of contaminants and CO2 in the gas stream was causing significant increase in the project capital cost. The goal of the project was to reduce CAPEX and OPEX by at least 30%. Process data was compiled along with equipment design, sizing and costing for the base case. Thermodynamic property model was developed and the base case was simulated in detail. Our proprietary conceptual design techniques for separation system design were used to identify process alternatives for improvements over the base case. Process alternatives were then evaluated for CAPEX and OPEX improvements. New intellectual property was generated during the project for the Client. Selected gas separation system that uses distillation was found to be the lowest cost alternative and resulted in more than 50% reduction in CAPEX and more than 35% reduction in OPEX. Project results were then successfully validated by the Client.

Join our mailing list to get the latest news & events.